Sugar Valley Bionet BIO 16

- Salt electrolysis equipment + Cu/Ag ionisation.

- Production: 16 g/h.

- Water salinity: 3 grams of salt per litre.

- Removable display.

- Optional automatic controls: pH, redox, free chlorine, conductivity, temperature.

- Self-cleaning cell with titanium plates.

- Includes 2-electrode ionisation vessel.

- New model with touch screen

- Manufacturer: Sugar Valley.

- Code: BIO16.

Bought together Usually

Actual product

Actual product

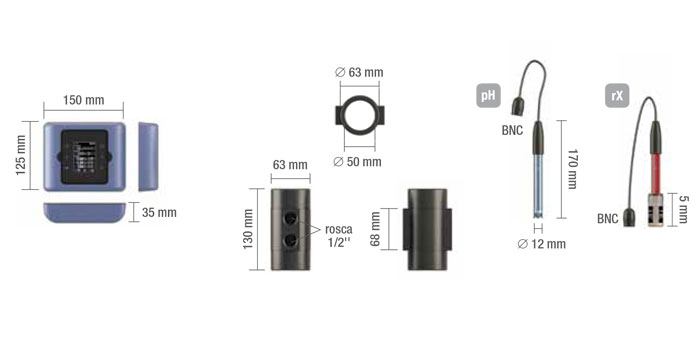

Technical characteristics

What is Bionet?

- A unique system for water that is twice as healthy.

- It combines the efficacy of the two most commonly used treatments in one.

- It achieves a natural chlorination-flocculation-anti-algae process without chemicals.

- It allows you to enjoy a more ecological and healthier bathing experience.

Advantages

- Clearly healthier.

- Double system integrated in a single electronic box.

- Each of the two treatments enhances the effectiveness of the other.

- Completely eliminates the use of chlorine and chemicals.

- Easy to install in any type of pool.

- Secure investment.

Characteristics of Bionet BIO

- Removable display.

- Access menus with security passwords.

- Safety: lack of flow / lack of salt / cover detection.

- Direct production in grCl/h.

- Cu/Ag ionisation (flocculant/algicide/bactericide)

- Optional automatic controls for pH (+/-), redox, Cl, conductivity and temperature.

- Safety: dosing time exceeded.

- Setpoints, waiting times and dosing configurable with patterns or at a single point.

- Automatic or manual operation.

- Compatible with VISTAPOOL remote control by cable or via WiFi.

How does the Cu/Ag electrolysis and ionisation system work?

Salt electrolysis.

Salt electrolysis systems generate chlorine from the common salt dissolved in the water. The salt necessary for its operation must be added to the pool in a concentration of 3-4 kg/m3. The chlorine generated destroys the organic matter and pathogens present in the water, transforming it back into sodium chloride (common salt). The products decompose, act and regenerate again.

Principle of operation

SALT ELECTROLYSIS

The traditional form of water treatment in swimming pools consists, fundamentally, of adding chlorine in any of its commercially available forms.

SALT ELECTROLYSIS SYSTEMS provide a new concept for the treatment of your pool, improving the quality of the water, avoiding the handling of chemical products and simplifying maintenance tasks as they generate chlorine from the common salt dissolved in the water. The salt necessary for its operation must be added to the pool in a concentration of 4-6 kg/m3 (5-6 times less than sea water). The salt is added to the water and chlorine (Cl2) is produced at the anode of the electrolytic cell by the following electrolysis reaction:

2NaCl+2H2O=2NaOH+H2+Cl2

(salt+water=soda+hydrogen+chlorine)

This chlorine dissolves in water to form hypochlorous acid:

Cl2+H2O=HOCl+HCl

(chlorine+water=hypochlorous acid+hydrochloric acid)

The hypochlorous acid oxidises the bacteria. As can also be seen, another product is generated, active oxygen (O2), which adds extra disinfectant power to the process, thus sterilising the water:

2HOCl=2HCl+O2

(hypochlorous acid=hydrochloric acid+oxygen)

Once the water has been disinfected, the hydrochloric acid reacts with the caustic soda in a neutralisation reaction, giving salt and water again. Hydrogen and oxygen react to form water:

NaOH+HCl=NaCl+H2O

(soda + hydrochloric acid = salt + water)

It is a closed process in which no product is lost.Salt should only be added once when the pool is filled. Only small periodic replenishments should be made due to water losses during filter rinsing.

The chlorine generated destroys the organic matter and pathogens present in the water and is transformed back into sodium chloride (common salt).

The products decompose, act and regenerate again. This explains why the salt concentration remains constant.

SUGAR VALLEY BRANDS, based on the working principle of salt electrolysis: HIDROLIFE, BIONET

COPPER (CU) AND SILVER (AG) IONISATION

The combination of 2 components Copper and Silver with disinfection capacity increases the effectiveness of each of our systems in a wide range of ways. If, in addition, in the case of cold water, it is supported by the presence of a third component that can be combined (chlorine), the disinfectant progression is geometric.

The use of metals as disinfectants in water apparently dates back to ancient times, when the Phoenicians inserted silver coins in ceramic and copper amphorae to preserve water.

The Greeks found that putting copper coins in the jars prevented the water from being corrupted. The Egyptians, on the other hand, put silver coins in the jars to prevent contamination.

In the Middle Ages, mothers knew that feeding their children with silver spoons protected them from many diseases.

Many airlines use silver ions to protect the water they give passengers to drink on their flights. In more than 70 countries, silver ions are added to beverages, beers, spirits and wines.

In America, during the colonisation of the old west, there was also the custom of introducing a silver dollar for the preservation of water barrels.

Oxidation Reactions

The ion-producing reaction (at the anode)

Cu++ Cu2+ + 2e-

Ag++ Ag+ + 1e-

James C.V. 1971, reports that all silver salts are bactericidal and that silver particles dissolved in water at a concentration of 10-5 is toxic to E. coli and Bacillus types.

The Cu/Ag ionisation technology available today was developed by NASA at the beginning of the space programme, in order to have a safe method of water purification to take into space.

SUGAR VALLEY BRANDS, based on the Cu/Ag ionisation principle: BIONET, AQUASCENIC ULTRAVIOLET.

Data Sheet

- gr/hour CL

- 15-19 g/hour

- Recommended pool size

- 20-50 m3

- With pH control

- No

Might Also like

- On sale!

- Top Sales