AFM Grade-3 active filter glass in 21 kg

- AFM grade-3 active filter glass.

- Bag of 21 kg.

- Granulometry: 2-6 mm.

- Suitable for all types of sand filters.

- Maximum efficiency in particle retention (see graph).

- Reduces water demand.

- For filters with a diameter greater than 1000 mm:

70% AFM grade-1 (upper part)

15% AFM grade-2 (intermediate part)

15% AFM grade-3 (lower part)

Technical characteristics

AFM activated filter glass

AFM activated filter media is a direct replacement for sand, doubling the performance of sand filters without the need for additional infrastructure investment. AFM resists biofouling, biocoagulation and transient wormhole channeling of unfiltered water and never needs to be recharged or replaced.

AFM is a highly engineered product made from a specific type of glass, processed to obtain the optimum particle size and shape. It is then exposed to a 3-step activation process to increase its surface area up to 300 times for superior mechanical and electrostatic filtration performance

what is AFM activation?

AFM activation is a patented three-step process where the surface structure of the glass is changed at the molecular level. The glass is an aluminosilicate and the activation process uses existing properties of the glass. This is why Dryden Aqua only uses glass from green containers.

Additionally this production process enhances the properties of the glass:

- Increases catalytic properties

- Controls the surface charge density

- Increases surface area

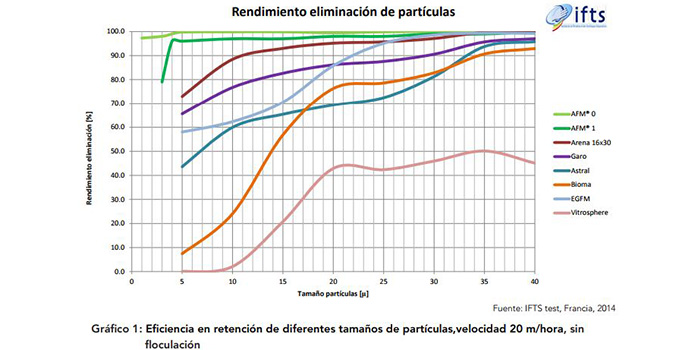

Test 1: Retention efficiency of different particle sizes

AFM retains more than 95 % of all particles in water down to 4 microns. The best that top quality sand and other crushed crystals can achieve is 20 microns with an efficiency of 95%. The AFM grade 0 is capable of retaining particles down to 1 micron with an efficiency of 95%. AFM grade 0 has been developed for optimum filtration where flocculants are not used. The results have been obtained with filters operating at a speed of 20 m/hour without flocculants. Therefore, the results correspond to a direct comparison between the different filter media. At lower speeds, the AFM® improves exponentially.

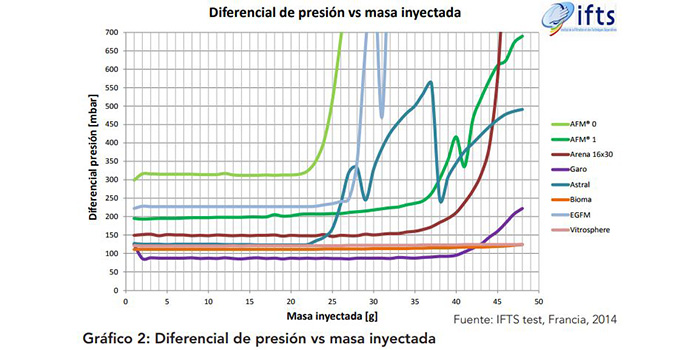

Test 2: Pressure differential vs. injected mass

ISO CTD particles were injected into the process water to test the ability of the different media to retain the particles in the water. When particles are retained from the suspension, the pressure should be gradually increased in the filter media until it eventually becomes blocked. Other media such as Vitrosphere were linear as most of the particles simply passed through the filter media. Astral glass was shown to be very unstable and allowed retained solids to pass back into the water.

The ability to retain particles is very important in any filtration system. In drinking water systems and swimming pools where cryptosporidiosis disease poses a significant risk, filters must be stable and capable of retaining parasites. Sand and AFM were the only products to offer a stable filtration barrier.

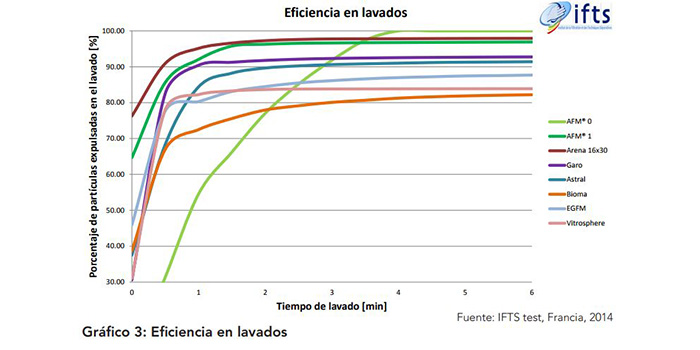

Test 3: Washing efficiency

The amount of material expelled during a given washing time was measured with all filter media. The data in the graph confirms a wash efficiency of 97% for AFM and sand. AFM 0 achieved 100%. The closest crushed glass was Garofiltre with 93% followed by Astral with 92% and EGFM with 88%. What is retained in a filter must also be able to come out. If this is not the case, the retained organic matter will be subject to bacterial metabolism leading to a possible bio-coagulation of the filter medium due to alginates secreted by bacteria and mineralised biofilm layers.